Big pet food companies claim the high ground in animal nutrition – but is kibble really all it’s cracked up to be? We break down the manufacturing process to find that maybe kibble is just today's 'dog cake'.

In our earlier post, The History of Modern Dog Food, we explained how dog food began from a cake-like product way, way back in 1860. You could argue, it's been downhill from there.

Just as in human food, it's a trade-off, isn't it? Convenience and low cost vs fresh and healthier. I'm not saying that all processed food is unhealthy however, as outlined in the book, Eat Like The Animals, (we introduced that here), ultra-processed human food tends to be low protein, low fibre, high carb...the result is that we're always trying to fulfill our protein appetite and eating too much food in the process.

What does this have to do with dog food? Well, when you think about it, kibble is really just the animal equivalent of ultra-processed human food. If convenience is more important to you than good health, well then, that's your choice.

You may have picked up a bit of bias here. Let me be crystal clear: my belief is that usually, fresh food is best. And by fresh, I do mean minimally processed. The result is that I DO have a bias against dog biscuits. And I'm not alone.

As it happens, I haven't always felt this way. It's a view that has formed, the more I've read about what's good for our own health, and good for the animals in our care - who don't have free choice over their food. With that in mind, let me share a few things that began to concern me about kibble.

Firstly, do you know what the manufacturing process is for making dry dog food?

Here's what happens, basically:

- You get a bunch of processed ingredients from various sources - which may include bits of animals that we aren't allowed to eat.

- That goes into a hopper, where it gets warmed up and gelatinised.

- Then some humectants or plasticisers are added.

- It gets really heated up, and then forced out through an extruder.

- It's dried out.

- Cooled down.

- And then packed.

So, what you ask, is wrong with that?

Let's go back through the production process and look at the issues, step by step.

Step 1: Dry ingredients

To get ingredients into a form that can go through this production process, rendered proteins are typically used. Rendering cooks and dries meat carcasses, offal and potentially other contaminants (plastic, metal (1)) into a dry product.

Rendering is done at high heat, from 120°C to more than 175 °C. At these temperatures, any fat in the material will essentially fry the material being rendered, leading to a relatively crispy product.

When ground, as is typical for by-product meal, the crispy texture creates high shear and the shear forces disrupt the native structure of the protein molecules. The combination of the high temperature and the shear, denatures a substantial portion of the proteins in the rendered meal. (2)

The structural change in the protein is a possible trigger for food allergies. Research shows the immune system may not recognise the altered protein structure and treats it as a foreign invader. (3)

Step 2: Pre-conditioning

At this stage, the dough is heated in the pre-conditioner prior to being introduced to the extruder. Here, starch ingredients may be mixed with water in the pre-conditioner. When the starch-containing dough is forced through the extruder at high temperature and pressure, the starch gelatinises and expands, forming a “puff" or “kibble” as the dough comes through the extruder die, the kibble being somewhat less dense than the dough prior to extrusion.(4)

Artificial colours, flavours, preservatives, and other additives used in some commercial dog food can damage a dog’s internal organs, especially the liver. (5)

Step 3: Extruding

The extruder is where the primary cooking phase happens. The dough is cooked under intense heat and pressure as it moves toward the open end of the extruder. The hot dough then passes through a shaping die and knife (similar to the action of a meat grinder) where the small pieces expand rapidly into kibble once they are under standard air pressure.

Here, viscosity-increasing agents, such as xanthan or other gums (as derived from a natural source, chemically modified, or fully synthetic), carboxymethylcellulose (CMC), pectins, agar, or gelatin are added to adjust specific mechanical energy (SME) during extrusion.

The extrusion process primarily destroys vitamin A, vitamin E and the B-group vitamins in dry food ingredient mixtures. Keep in mind that B-group vitamins are water soluble, meaning your pet’s body can’t store them – they must be provided daily through diet. (6)

Step 4: Baking

The kibble is dried in an oven until its moisture content is low enough to make it shelf stable like a cookie or cracker.

Dogs’ natural diet is up to 70 percent water and their bodies have evolved to consume a diet that is rich with water. The manufacturing process makes kibble too dry, which means your dog’s body has to provide enough moisture to reconstitute the food in their digestive tract.

“A lifetime of minor dehydration is stressful to multiple organ systems, but most notably the kidneys." (7)

This is also an issue for cats too. Research (8) also shows that cats drink more water when offered dry diets (vs when eating wet), but they don’t drink amounts that would compensate for the significant reduction in moisture content of these diets. However, when fed high moisture diets urinary tract health improves and weight is reduced.

It's worth noting that diabetes in cats is now a world-wide problem, as is obesity and chronic kidney disease.

Step 5: Coating

The kibble may pass through a machine that sprays on a coating, which is generally a flavour enhancer. Additional fats may also be added after extrusion, with fat-based or fat-containing coatings.

Fats added in coatings are susceptible to oxidation, which causes the fat particles to break down into smaller compounds such as malondialdehyde, and the fat becomes rancid. Rancid fats can destroy vitamins, which can lead to vitamin deficiency. To avoid rancidity developing, preservatives are added.

They're just some of the issues that arise at particular stages of the kibble-making process. However, there are others.

Before I go on, it's worth understanding why carbs are in kibble in the first place. It's certainly not because dogs need them. They're there, fundamentally, to make manufacturing more efficient and cost effective. And as we'll see in following article, dogs don't need dietary carbs.

There's something else that happens during extrusion though, and it's to do with protein.

Researchers, using hair analysis of all things, have found that heating a mixture of meat ingredients and grains at higher temperatures as is done in the extrusion process to create dried dog food or kibbles may produce PhIP. PhIP is a heterocyclic aromatic amine (HAA) that is formed during the cooking of meat, poultry, and fish. PhIP is also a rodent carcinogen and thought to contribute to several diet-related cancers in humans.

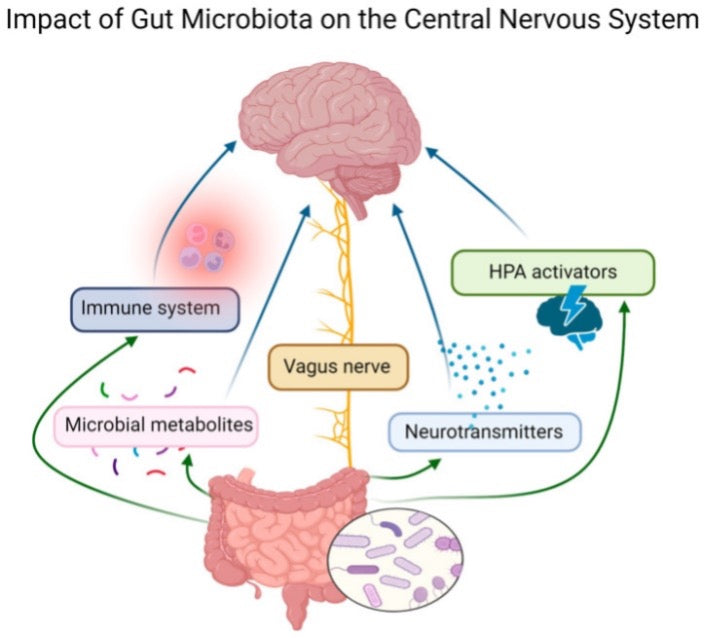

In addition, when a protein joins with a carbohydrate, the biochemical result is a compound —advanced glycation end products (AGE) — that can cause widespread inflammation and damage in the body.

In humans, a direct link exists between the amount of processed foods consumed and the level of AGE in the blood; AGE has also been shown to exacerbate diabetes and interfere with kidney function. Research now shows that the less processing that occurs in pet food, the less heat applied, the more moisture maintained, and the lower the AGE. (8)

In addition, dry fed dogs showed significantly elevated levels of homocysteine, a marker for systemic inflammation. Homocysteine levels and obesity are strongly correlated. (9)

If convenience is still at the top of your list after reading all that, read on to find out how to make feeding fresh almost as convenient as dry food from a bag.

SOURCES

- news/2018-06-19/pet-food-insider-lifts-lid-on-plastic-and-rubbish-goinginto-pe/9875184

- IAMS patent application: WO 2013/177143 Al3

- IAMS patent application: WO 2013/177143 Al3

- https://healthypets.mercola.com/sites healthypets/dr-karen-becker.aspx

- Martin, A. N. (1997). Foods pets die for: Shocking facts about pet food.Troutdale, OR: NewSage Press.

- https://healthypets.mercola.com/sites/healthypets/archive/2011/05/19/the-mainstream-pet-communitys-new-take-on-cat-and-dog-foods.aspx

- https://healthypets.mercola.com/sites/healthypets/archive/2009/07/07/pets-protein-dry-food-and-disease.aspx

- Based on research by Dr. Danielle Conway, the first American Holistic Veterinary Medical Foundation (AHVMF) fellowship recipient, https://healthypets.mercola.com/sites/healthypets/archive/2015/12/10/processed-pet-food-causes-disease.aspx

- Buckley, Catherine MF, et al. "Effect of dietary water intake on urinary output, specific gravity and relative supersaturation for calcium oxalate and struvite in the cat." British Journal of Nutrition 106.S1 (2011): S128-S130.

- Based on Dogrisk metabolomics study to better understand the relationship between canine health and diet https://healthypets.mercola.com/sites/healthypets/archive/2017/11/08/kibble-fed-dogs-metabolicstress-levels.aspx