We work with our food tech partners Viridian Renewable Technology, to source the black soldier fly larvae meal, that does so much heavy lifting in our Planet A products. And not just for 'crude' protein!

Yesterday's bread; tomorrow's pet food.

Did you know that Australia discards about 7m tonnes of food every year? THAT'S. A. LOT. And when lost to landfill, the result is significant greenhouse gas emissions - not to mention wasted land and water use.

But Viridian is not so much a waste processor as a protein manufacturer. And it's the tightly controlled use of clean, pre-consumer food by-products (like bread!) as inputs to their insect protein manufacturing process, that really gets us over the line.

Their model gives them traceability about the origin of their inputs and confidence about their food safety. And diverting leftover human-grade food products from landfill prevents wastage of valuable resources and generation of greenhouse emissions.

They're using the black soldier fly larvae as a key part of this process. The black solider fly larvae has a voracious appetite, and can turn organic waste into valuable biomass very fast, with a low impact on resources: 1 tonne of insects can be grown in 7 days using a land area of only 5 square metres .

Because the mature black soldier fly doesn't eat, they're very efficient at storing nutrients as larvae. And the nutrient profile - amino acids, fatty acids etc - is awesomely good for our purposes at Planet A.

Carbon neutral manufacturing

As a company, Viridian is on a mission to:

- Use their insect-based manufacturing technology to create carbon-neutral pet, plant and animal feed ingredients.

- Replace traditional non-renewable ingredients with consistent and nutrient rich insect derived products.

- Improve existing food production processes to promote better palatability and health and reduce environmental impact.

Viridian's processing methods are based on EU regulations for insect protein. Currently there are no real standards in Australia to ensure manufacturers are producing safe and high-quality insect products, something Viridian is lobbying for.

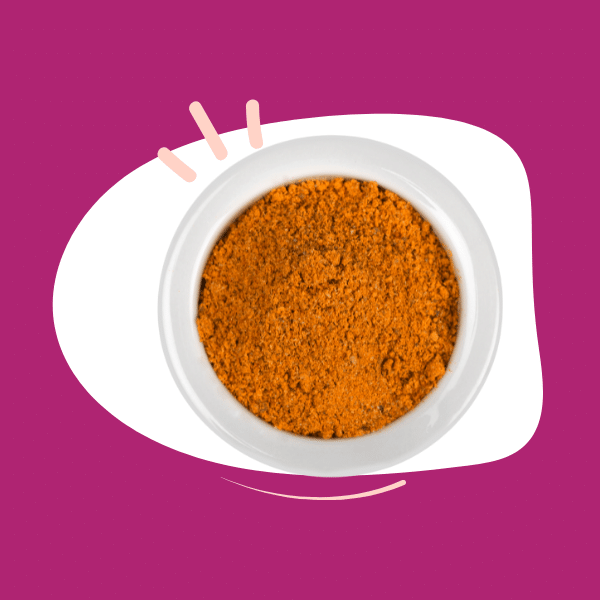

The technology they've developed to create their protein meal is highly specialised to deliver the best flavour and an excellent nutritional profile. Many other manufacturers use a range of machines including microwave dryers that have a strong impact on product quality.

The production of 1 tonne of Viridian’s insect protein powder creates 2.5 tonnes of insect fertiliser and utilises 14 tonnes of food by-products, preventing an estimated 28 tonnes of greenhouse emissions, resulting in a net offset of over 25 tonnes of carbon emissions per tonne of protein powder.

That's a helluva lot less than the emissions for beef!

(Images: Viridian.)